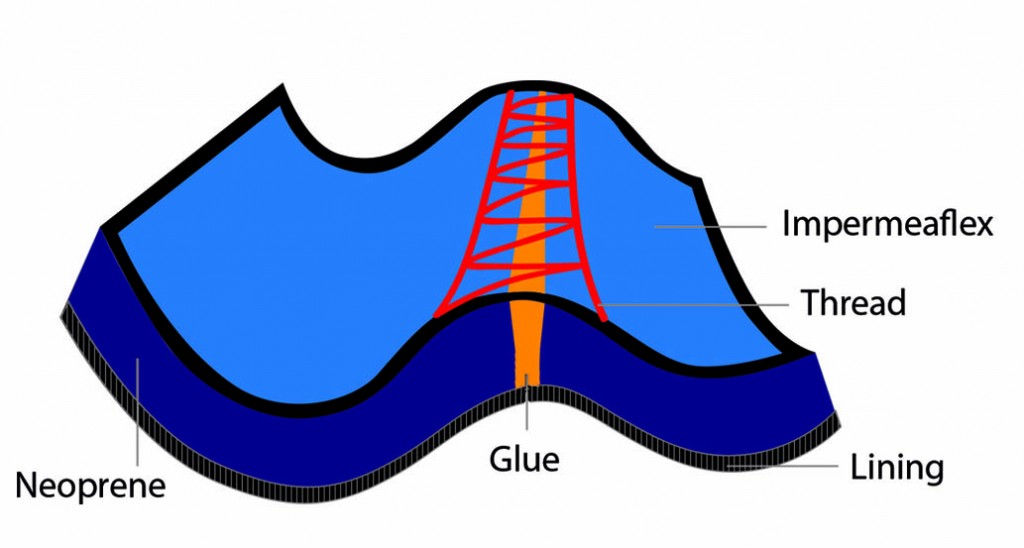

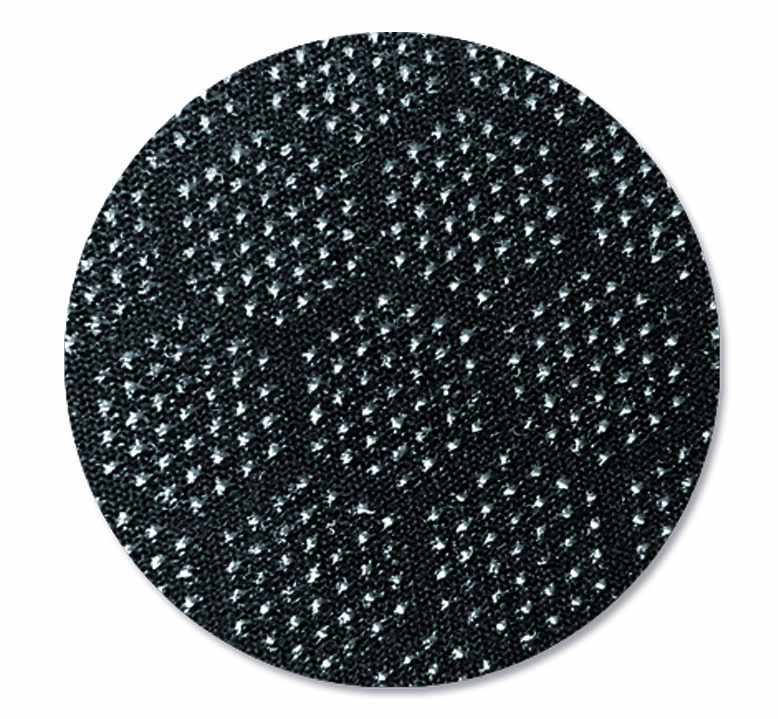

The easiest, safest and fastest way to don the suit is to do the following: 1- Take a half empty bottle of water, and squeeze inside it some hypo allergenic and fragrance free hair conditioner. I would say the size of a small egg. 2-Shake the bottle until you get a diluted yogurt-like liquid 3- Pour some in each leg of the trousers, while gripping tightly both leg openings together to prevent the liquid from exiting too early. 4- Shake the trousers and massage them, in order to coat the lining with the gooey solution 5- Slip one leg at a time, with toes pointing downwards, in order to avoid nicking the neoprene with the toenails. 6- Use palm of hands to pull and adjust 7- Do the same with the jacket. Pour from the wrist cuffs and also from the waist area and make sure the shoulders get a good share of the solution. 8- Wear either head first or one arm at a time. Adjust the elbow part to fit in place 9- Until you get the feel of it, try and use the palm of the hands in pushing / pulling / rolling motion. This will eliminate accidental nicks and tears. 10- Once the successive stages become a fluid motion, this whole suit can be donned in less than a minute. 11- Socks can be worn dry, and this should be done in a roll and squeeze motion like a condom. If finger tips must be used, make sure they are on the fabric lamination side, never on the neoprene lining. To remove the socks, just roll them outwards and keep rolling while pushing. 12- The 5 finger gloves can be we worn slightly lubed. To take them off, just roll out a few inches, pull where the inner wrist is and blow as you would a trumpet, which will; cause them to come out instantly. 13- To take off the jacket of the suit, you have 2 methods: a- You unbuckle the clips and pull both sides of the jacket up a few inches, forming a “canal” – Pour water and start pulling as it gets heavier, while adding more water. The heavier it gets, the faster it will be to just “peel” the whole jacket off your torso. This can be done before coming out of the water (much faster, easier and healthier this way). b- Say you are out of the water and need to just take it off without water, then unbuckle the clips, lift up the edges and bend forward 90 degrees, so that the beaver tail part flaps on your back and you can grab it with one, then both hands. Start pulling slowly, without exerting sudden or excessive pressure. Keep pulling until you can get both elbows inside the rolling out area, push outwards and upwards and voila. 14- For the trousers, just roll them down until you reach the feet. Once the bundle is at its lowest below the calf area, point your hands BACK to your legs and push down. This will impose an even and gentle stretching of the trousers opening, which will “slide” them out completely. 15- I know many divers like to use baby powder. I wouldn’t. 2 reasons: 1- It is not as effective as the conditioner mix above and, (2) If inhaled, it will cause discomfort to the lungs which you certainly do not need before a dive. Not to mention it is not healthy and messy. 16- For maintenance, rinse with freshwater, turning it inside out. Hang to dry completely. This shouldn’t take long, due to the absence of fabric lining. You can leave in the sun but for a very short period of time only. Short enough to dry it and let the UV kill the bacteria if any. Too much sun will damage the neoprene. The 3 enemies of Poly-Chloroprene (100% CR Neoprene) are the Petroleum based lube (such as KY Gel) Ozone and the UV’s – Also storage in excessive heat (IR) will age it faster and make it harder with time. 17- If there are nicks and tears, do as mentioned in (16) and then once totally dry, use the Yazbeck Glue to fix it. Takes about 15 minutes total and it’s like new again and you can dive in it right after fixing it, if done properly as per instructions. 18- If diving repetitively for days at a time, soak overnight in a bac of water to which you will add a cup of distilled clear vinegar (5% Acetylic acid) – This will prevent an eventual bacteria breeding that may cause skin staph infection. Better to prevent. Remember that this bacteria grows in an alkaline environment (sweat, urine) – To counter it, vinegar is magic. When diving daily long hours each time, I would even mix some vinegar to the water and conditioner mix, as a prevention measure to maintain the skin in an acidic environment, which in the worst case scenario will be neutralized by the aforementioned alkaline conditions. 19- On a side note, I would recommend a mixture of 95% Pure or Isopropyl alcohol with 5% Liquid Glycerin, to be added to 30% of Vinegar (5% Acetylic Acid) and dropped in your ears before and after dive. If you always do this, you will keep ear infections at bay. A thick and rubbery polyurethane formulae that is elastic and supple, yet scratch-proof and very durable. It is applied in multiple layers through a silkscreen process to the areas where protection from abrasion as well as an anti-slip grip is needed, such as gloves palms, socks soles, speargun chest loading pads, knees and elbows. Smoothskin is actually the upper and lower crests of the master foam after it comes out of the mold. Think of an angel cake that was just baked. Imagine the crusty surface that is smooth since it was the one exposed to the heat of the oven. We at Yazbeck, use that “crust” as a waterproof seal. You will find it in most of the Yazbeck wetsuits used as a face, wrists and ankles / leg opening seals. This is also the part that enters in the fabrication of our legendary Freedive Hunter socks. First, the loose threads have to be cut with sharp scissors. Then it must be washed with fresh water to remove salt and dirt. Then after it has well dried, neoprene glue is used to bond it again. (Use SOFT neoprene glue, that stays soft after curing, such as Black Magic) 1- Make sure the surface is washed with fresh water and that all dirt and sand is removed. Then let the suit completely dry. 8- Refer to our Yazbeck How to Repair your Wetsuit Tears Video – Click Here to View Now 1- Make sure the surface is completely dry The Hamour Camo pattern is definitely the most effective Camouflage design ever to be created. It is a world premiere in many aspects. At Yazbeck we are concerned about the earth’s environment and we want to emphasize that the YAMAMOTO Neoprene used in our products is not petrochemical based but from a Limestone based polymer with a 99.7% calcium carbonate concentration. This point is also acknowledged for greater acceptance in the market of the medical products made of Yamamoto’s neoprene rubber, which has been approved by the FDA. Calcium carbonate foam is much cleaner and more eco-friendly compared to petroleum-based rubber even from the point of its manufacturing process; because, we don’t use petroleum as the primary resource. The quantity of heat for processing and producing these raw materials is one tenth that being used in refining the equivalent petroleum neoprene products on the market today, and the heat generated is utilized for the raising of eels which are used as a food resource in Japan. The source of heat that is generated is from used tires and the electric power we use is generated from several dams and power stations constructed below the high mountain range near our facility. This special technology to convert limestone to neoprene rubber is considered environmentally clean and friendly in relation to how neoprene is traditionally manufactured. The material can be processed to its unique low viscosity at low temperature. The Yamamoto Neoprene manufacturing process is precisely controlled at below 0.5 centigrade. Special compound to match limestone. The brief processing method of the limestone is to make acetylene gas spring up by burning the tire and to liquefy it by the chemical polymerization, then to dry it to chips. The Japanese special technology to convert the limestone to the rubber is an advanced technology that not only produces the finest material for making Yazbeck wetsuits, it is also to help protect the Earth’s environment Impermeaflex® is a unique and exclusive fabric specially knit from a blend of ultra-supple, high performance, specially knitted synthetic fibers. Contrary to the traditional fabrics normally used in the past by the industry, Impermeaflex® has less tension and stretches 4 ways, at more than 3.5 times its own length, making it even more elastic than neoprene itself. Therefore, Yazbeck wetsuits are so supple, they fit and feel like surgical gloves. Features: – The look: Rich, Glossy, Deep and the highest resolution sublimated dye, like print media. Produces 3D and Holographic Camo effects – The feel: Smooth, silky, soft and supple unlike any other laminating fabric. – The functionality – Hydrodynamic: it will cut through water faster, because unlike other fabrics, it’s hydrophobic. Waterproof: The wetsuit will therefore be lighter out of the water and will dry in minutes. Imagine how nice and warm it is to wear it again for another dive a few minutes later. Suppler: Will stretch more and allow for an optimal comfort and much better fit. This means a longer breath-hold with each dive and longer hours in the water due to the increased freedom of movement. Stronger: It will resist wear and tear more than traditional fabrics. Resilient: it will not creep nor lose its properties as it ages. Resistant: Will never bleach under duress and the elements, such as U.V or salt water. Therefore it will last much longer than other fabrics. FreeDive Hunting photographers, videographers and spearfishers, seek that unique moment for the perfect shot.Whether it is for that once in a lifetime photo, video footage or trophy game fish; Holoblend® will give freedive hunters around the world the edge. It is the answer to their ultimate quest; blending in and getting their subject to get as close as possible to them. Spearfishers want to outsmart that elusive fish. On land or in water, blending in the surrounding is what preys as well as predators have been perfecting since the dawn of time. On any outing, hike or dive, just take the time to really look around you. You will start seeing this pattern everywhere; plants, insects, reptiles, mammals, birds, mollusks, crustaceans and fish. Camouflage is a magical art. Holoblend® is the answer to every freedive hunter’s ultimate goal; getting as close as possible to their subject, for that perfect and, sometimes, one in a lifetime shot When stalking fur and feather game, each careful extra step of barely one foot would change the whole perspective for a hunter’s trained eyes. Suddenly, the tiny flag of a cottontail in the corn field, the contour of a grouse against the autumn’s carnival colored maple leafs, or the black dot, betraying the eye of an all-white hare bundled in the snow, would make all the difference between an exquisite family game dinner with the glamorous tales for dessert, and the sorry “been –skunked” feeling over a bitter beer downed with the story of the one that got away. Make no mistake; a great Camouflage makes all the difference. No matter how good and experienced a freedive hunter is, properly blending in the surrounding does give an edge and will increase the chance of success. Sure, we all know that the fish can see, feel, hear and smell us, no matter what. That’s a fact. Not only fish can see us, but unlike most animals, they see us in color too, since their eyes have all 3 types of RGB color detecting cones just like humans do. Fish can also smell us. So let’s make sure to skip the aftershave or deodorant before the morning dive ? Fish can also hear us. Sound is stronger and travels almost 5 times faster in water than in air. So they can even hear our heart beat. And finally, fish can sense and feel our presence in the water. Let’s not forget this is their home. They can feel the not so subtle current change as it moves around us when lying in wait, and can even guess our size based on that. So why bother wearing a Camo wetsuit? Well, we all know the old adage: “Curiosity killed the cat”. The fish feels, hears and smells an alien in their backyard. They “know” we’re there. But they need to take a look. That’s simple curiosity. They usually almost always manage to sneak up on us from behind. If what they actually see does not correspond to what they “know” and “feel”, this will trigger another scouting response. Holoblend® is breaking-up our one big shape and form into several smaller parts. That’s what camouflage does to trick the eye / brain connection. Chances are they will come for a closer look and voila; the edge we were looking for. The Yazbeck Camo Thermoflex wetsuit was not only the world’s first 3D wetsuit Camo, but it was also the world’s first Camo on a Lycra based fabric. The only Lycra laminated neoprene wetsuits at that time were a single color, mostly solid black. And even these were very rare and very expensive then. The introduction of the 3D Camo design and printing was a game changer 10 years ago. And when the Yazbeck Camo Thermoflex model wetsuit was released in 2006, it took the freedive hunting and spearfishing world by storm. When it was exhibited at DEMA 2008 in Las Vegas, the most famous diving brand names in Europe and the rest of the world, tried to copy its patterns, materials and techniques. But they all failed. Even today, 10 years later, never has anyone been able to duplicate it or come up with anything even close. The main reason for that is simple: its cost. See, no one in the industry is willing to spend the resources it takes to come up with such a material, since “the spearfishing wetsuit” as they like to call it, is a really small niche item. Its mass production is almost impossible when the whole world market for it does not even represent 1% of the wetsuits in general. Also being very complex to create, if this product was worth patenting for any company, it would actually involve investing on several patents and not just one. This isn’t just one novelty, but a combination of novelties that resulted in such a revolution. Therefore, only an entrepreneur with enough experience, creativity, passion and dedication to this sport could pull this one off. Profit had to come last on the priority list, which is, as we all know, an absolute no-no for big companies. Before Yazbeck started it, none of the other brands had ever used sublimation printing on Elastane before. (Educate yourself about the sublimation printing method by searching for it on Wikipedia.org).Those who do, have copied the idea and method from Roger YAZBECK, except that they do not have the proper materials for it, therefore their resulting wetsuits are a failure. On the other hand, the brands that use other fabric printing methods and heavily market their designs as 3D Camo are merely copycats, albeit bad ones. However, there is a plethora of things that make a Yazbeck freedive hunting wetsuit and only Roger Yazbeck holds all the threads. This is why he has chosen to actually live in China most of the time, to supervise each and every Yazbeck wetsuits production in person. Not even a sample can be manufactured unless he is present in person at the factory for the pre-production, work in progress as well as post-production final quality control and inspection. By end of 2013, Yazbeck had launched the 4th generation freedive hunting and spearfishing wetsuits, whereas the others are still struggling with the first one and still botching it. This is the natural evolution of the 3D Camouflage that Yazbeck created in 2004. It was a first, introduced to the freedive hunting and spearfishing world in 2005 through the launching of the preeminent Yazbeck Camo Thermoflex model wetsuit. Holoblend® is another world exclusive by Roger Yazbeck and can only be obtained through a sublimation printing process on Impermeaflex®. Since 2004, Roger Yazbeck has designed, created and produced more than 15 different, unique and exclusive camouflage designs, patterns and colors. Under his own Yazbeck brand, 7 Holoblend® Camo wetsuits have been launched so far: the “Camo ThermoFlex” (2005 to 2007), then the “Snyper” and the “Kelpstalker” (2008). The “Hamour”/“Scorpionfish” (2014). The 5th and 6th Holoblend® designs are now taking the world by storm, even before their official launching in the U.S.A. These are Yazbeck’s 2015 creations: “Carbone” and “Thazard”. The 7th design is now in testing as a prototype and will be launched in Hawaii in 2016 as the model “Nohu”. Yamamoto’s technical rubber is called “Chloroprene.” The performance of Chloroprene is dependent on the raw material and its closed cell condition – if one or more cells are interconnected or if the wall of an individual cell is ruptured, the performance of the rubber is impaired. Yamamoto has been successful in producing the perfect independent closed micro- cell structure. This has been achieved by employing a special polymer derived from limestone along with the most advanced manufacturing techniques – all developed by Yamamoto Corporation, Japan. Yamamoto’s rubber is made from limestone – over 99.7% calcium carbonate. The function and quality of technical rubber is decided not only by the purity of the raw materials – the limestone that goes into Yamamoto’s technical rubber comes from one source – but also by the independent closed micro-cell structure. The independent cell structure offers the following advantages: The closed cell content of Yamamoto Chloroprene is more than 93%, 22-33% higher than competitors whose closed cell content is typically in the 60-70% range. What does all of this mean to the Divers?This means that the divers are assured of the lightest weight, warmth and comfort. Why? Simple. Check out the features below: The 100% CR Neoprene used in the Yazbeck wetsuits is a rectangular sheet that was sliced to various thicknesses. At its first stage, the sheet is all rubber, called a master foam or slab. Both surfaces look and feel the same: smooth and very soft to the touch rubber (skin), as if polished. When the Neoprene sheet is sliced, thousands of minuscule suction cups are exposed, like a rich “soufflé” or “chocolate-mousse”, filled with air bubbles. This is why divers must lubricate the wetsuit before donning it. Some use talcum powder, soap and water or hair conditioner and water. At this stage, the Neoprene sheet is ready for the final treatment. It could either be turned into a “smooth-skin-out, open/split-cell-in” wetsuit, or into a “Nylon (or Lycra) out, split-cell-in” or Titanium lined wetsuit . The second choice, is obtained by laminating the sheet with Impermeaflex® or other fabric. We then have the perfect “second skin” for a Freediver: “the “split-cell-in”, also referred to as “open-cell” or “skin-in”. NanopreneShield® is another Yazbeck proprietary blend of Titanium Oxide lined directly on the naked open cell (split-cell), rendering it slick and smooth like Teflon™ and adding extra properties to the wetsuit, such as: 1- Ease of donning; no need for lubrication NanoPreneShield® and BioTermic® are special coatings mainly used to line, laminate or both, the split /open cell area of the 100% CR Yamamoto Neoprene. NanoPreneShield® and BioTermic® are basically the same except that the materials used in their composition differ. The former uses a Bio Ceramic which was invented by NASA in the early 70’s, in its quest for a heat-reflecting material that would protect the space vessels from overheating as they reenter the atmosphere on their way back to earth. The drive behind Yazbeck’s NanoPreneShield® and BioTermic® coatings was fourfold: 1- Unlike standard wetsuits fabric lining, Yazbeck’s NanoPreneShield® and BioTermic do not absorb water and prevent the wetsuit from “clinging”. So the diver is not greeted with cold when re-wearing a suit that has already been submerged in water. Comfort levels are significantly increased; 2- Typical jersey/rubber combinations allow for the growth of bacteria on their surface. Yazbeck’s NanoPreneShield® and BioTermic coatings are antibacterial 3- Fabric on one side only (top part, or lamination) allows for more stretch than on both sides (inside is fabric-less, or lining-free). When a wetsuit is lined with Yazbeck’s NanoPreneShield® or BioTermic® (coatings are applied inside), you gain all of the benefits, plus the added stretch; 4- Yazbeck’s NanoPreneShield® and BioTermic® are slick as Teflon® and reflect back most infrared (heat) radiation. This makes them the perfect barrier against heat transfer between the diver and the water and allow the diver to wear the wetsuit without any form of lubrication. 5- A fifth characteristic and the reason NanoPreneShield® and BioTermic® are the choice of top competitive freedivers is, when either is applied on the outside or the inside (lamination and/or lining) of the suit, it drastically reduces water resistance/friction(0.032). On the inside, it eliminates the friction between the skin and the wetsuit during motion, therefore reducing fatigue and consequently, oxygen consumption. And when applied on the outside, its increased hydrodynamics allows for deeper dives and faster times, while using fewer strokes. Yazbeck is the only manufacturer in the world who applies such coatings, directly on the “split-cell” surface, so the wetsuit remains an “open cell” (split-cell) wetsuit, but with the NanoPreneShield® and BioTermic ® phenomenal properties. Yazbeck Wetsuits are made using Yamamoto Japan Neoprene exclusively. That Neoprene, being of 100% CR closed cells Chloroprene, it owes its extraordinary and superior thermal insulation and comfort features, to the hundreds of thousands of tiny nitrogen bubbles trapped in the tiny closed cells within the Chloroprene foam of the Neoprene itself. This is similar to how a “thermos” works, using air for insulation. Air, being 80% nitrogen, is the best gaseous insulation agent. A commonly known “Open Cell” wetsuit (technically a “Split Cell Inside) is a wetsuit that is NOT lined at all. Once the slab of Chloroprene master foam has been mechanically “split” (hence the correct appellation “split cell”), it becomes pure rubber with tens of thousands of tiny craters, which used to be the closed cells with the nitrogen gas filling. They now act as suction cups, eliminating any space between the skin and the wetsuit. This is why a diver must lube such a suit before donning it, using water, or water and soap, or best of all; water mixed with some hypoallergenic and fragrance free hair conditioner. Freedivers generally refer to the best freediving wetsuits as “skin-in” or “open-cell”, when these wetsuits have no fabric lining. This is simply because wetsuits are divided into two categories: Wetsuits with fabric lining and wetsuits without fabric lining. By lining, we mean a fabric material, such as Nylon™ or Lycra™ that covers the inside of the wetsuit, which is in direct contact with the diver’s skin. However, both appellations are not technically correct. But we will compromise and accept them, in order not to complicate matters. “Skin-in” may also be what is referred to as “smooth-skin” inside. Meaning that the Neoprene sheet was used as is, without “splitting”, therefore defeating the purpose of a perfect fit, adhesion and waterproofing. Many wetsuit manufacturers will use this design and market the wetsuit as “open-cell” or “skin-in”, thus confusing the divers. Skin-in, or smooth skin in, is actually the upper and lower crests of the master foam after it comes out of the mold. Think of an angel cake that was just baked. Imagine the crusty surface that is smooth since it was the one exposed to the heat of the oven. Once you slice that part, the inside of the cake is spongy. Voila! We at Yazbeck Wetsuits, we use that “crust” as a waterproof seal. You will find it in most of the Yazbeck wetsuits used as a face seal, wrist cuffs and leg openings. This is also the part that enters in the fabrication of the legendary Freedive Hunter socks. However, Yazbeck never uses this part as a lining. It would defeat the purpose. The only linings that are acceptable to Yazbeck Wetsuits are either the “Open / Split Cell, Titanium Silver / Charcoal (NanoPrene Shield™), BioCeramics (BoTermic® ) , Impermeaflex™, or in the case of some thinner wetsuits and some gloves and socks models; Nylon, Plush or Lycra™ or Spandex™ The traditional wetsuit you find in dive-shops presents all of the following disadvantages: The Yazbeck wetsuit on the other hand, have none of the disadvantages listed above. Instead, it will; The Yazbeck wetsuit is made using the newest generation Neoprene that can only be manufactured in Japan. It must be 100% CR (Chloroprene)Neoprene, that’s why. The CR Neoprene relies on Nitrogen pockets for thermal isolation and the wetsuit can only be hand made by skillful professionals. The manufacturing procedure is very complex and takes a long time, because the wetsuit is first assembled, glued and then surface stitched only. It is so flexible, warm and comfortable, it almost feels like a «second skin». The Yazbeck wetsuits fit the freedivers like a glove, literally, giving them the sensation of being wrapped in a perfectly molded silky latex material, with that beyond description “Gel-Oh!” feeling.

2- Apply Yazbeck Neoprene Repair Glue on each broken edge and cover completely.

3- Keep both sides of the cut separated and wait until dry to touch (about 10 minutes or so, depending on weather and humidity in the air).

4- Apply a 2nd coat on each edge of the cut.

5- Wait again until dry to the touch, then CAREFULLY and PRECISELY join the edges.

6- Once edges are joined, press and pinch forcefully in order to squeeze out any tiny air bubble that may still be trapped between the 2 edges.

7- Once it has been glued, 2 things can be done:

2- Apply the Yazbeck Neoprene Repair Glue on each broken edge and cover completely. Keep both sides separated, do not connect them yet.

3- Wait until dry to touch (about 10 minutes or so, depending on weather and humidity in the air)

4- When both sides feel dry when touched, CAREFULLY and PRECISELY join the edges. Press and pinch forcefully in order to squeeze out any tiny air bubble that may still be trapped between the 2 edges.

5- Refer to our Yazbeck How to Repair your Wetsuit Tears VIDEO – Click Here to View

Its chameleon-like instant morphing, blends-in any surrounding environment, rendering different hues, depending on light, colors or shapes, with such a holographic effect, that it’s nothing short of magic.

Never before has a camouflage behaved so organically and is no coincidence, for it took us more than 3 years of research and development before we finally created it.

The “Hamour” would be impossible to reproduce with standard inks on any commercially available fabric, made by any other brand in the world, including DuPont’s famous Lycra™ and Spandex™, which both pale in comparison with Impermeaflex®, Yazbeck’s exclusive, hyper-flexible and hydrophobic lamination and rashguard fabric.

The ratio of closed cells of our neoprene is over 93%. This ensures lightweight and a lower specific gravity – essential qualities for wetsuits and swimwear.

The nitrogen gas inside the individual closed cells result in exceptional heat retention and efficiency. Super stretchability Our Neoprene’s highest elongation is 480 – 580% compared to that of the human skin’s maximum elongation of 60-70% available at the armpit.

The uniform micro-cell structure of our neoprene ensures that if any part of the material surface is defaced or scarred, new independent concave micro-cells are exposed insuring continued functionality.

2- Low friction; therefore reducing considerably the fatigue caused by the constant swimming movements

3- Bacteriotatic; bacterial rashes and odor inhibitor.

4- Heat Reflective; help sustaining diver’s own body heat, in order to maintain maximum core temperature

5- Feels like your own skin!

The latter, uses Titanium Oxide powder, which has numerous advantages, too long to be listed here. Both NanoPreneShield® and BioTermic® are therefore a coating applied to the exposed “split-cell” inside of some of Yazbeck’s wetsuits, Neoprene vests, gloves and socks.

Category:

What is...?

Category:

What is...?

Category:

How to...?

Category:

How to...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?

Category:

What is...?